What is 5S?

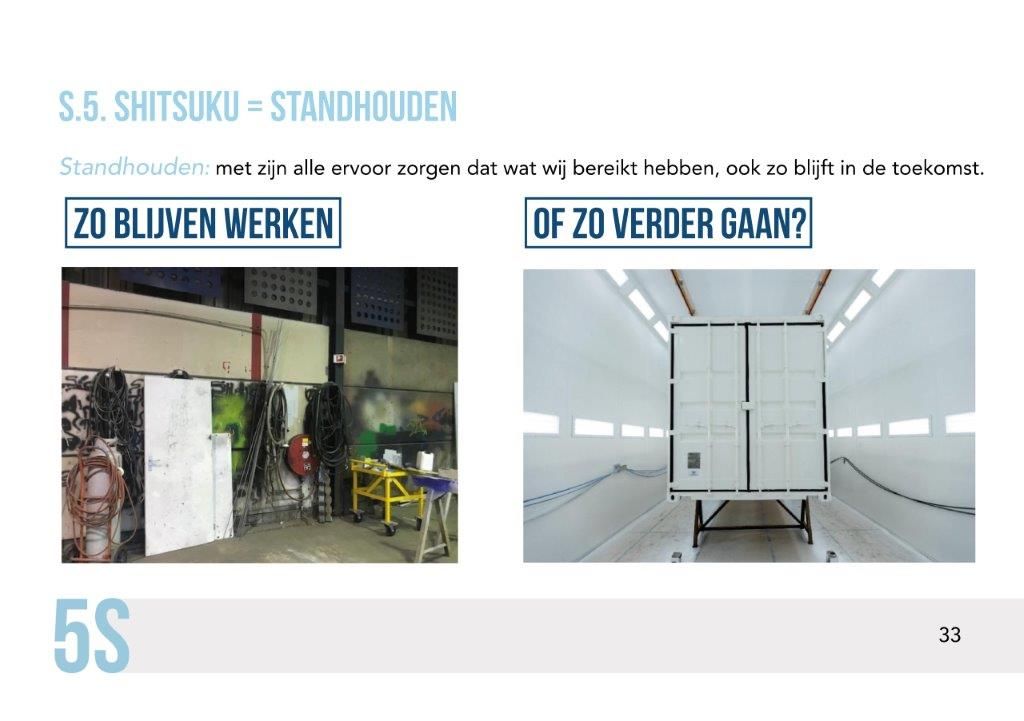

5S is a Japanese quality management system, in which each S represents a different aspect: set in order, sort, shine, standardise and sustain. This is the perfect system to achieve a tidy factory. No more grinders or grinding discs scattered on the floor, no more walls full of nude calendars and no more hazards due to random cables lying on the ground.

Why did we start applying the Japanese 5S system?

Once you start producing more expensive containers – one container for a large multinational had a 120,000-euro price tag – your workplace should look the part. Future customers can view our workplace with joy and respect. We can be more proud of our work and our workplace. Who wouldn’t want that? It elevates the factory. On top of that, the 5S system increases workplace safety and the quality of our products. Of course, this is a team effort rather than the work of a single individual. 5S is something you do together!

5S at Groenenboom

By now, we’ve gone through significant developments and try to adhere to the Japanese 5S quality system (of sorting, setting in order, shining, standardising and sustaining) wherever we can. We even have our own demo video of the 5S system at Groenenboom (https://youtu.be/1F6pceEN1xA ) and our own 5S guide with specific rules that apply at Groenenboom. This is ideal for instructing new employees and convenient for customers, as it allows them to see how we guarantee our quality at a glance. On top of that, our employees regularly receive training and attend toolbox meetings to retain the level of quality we have achieved. There are various safety posters in the factory to subconsciously make sure everyone remembers the 5S objectives. On top of that, we try to foster a mentality of constant development within the company as a continuation of the 5S system.